Do you need UN 38.3 testing or certification services for your batteries?

We are ready to test your batteries according to latest version of UN 38.3

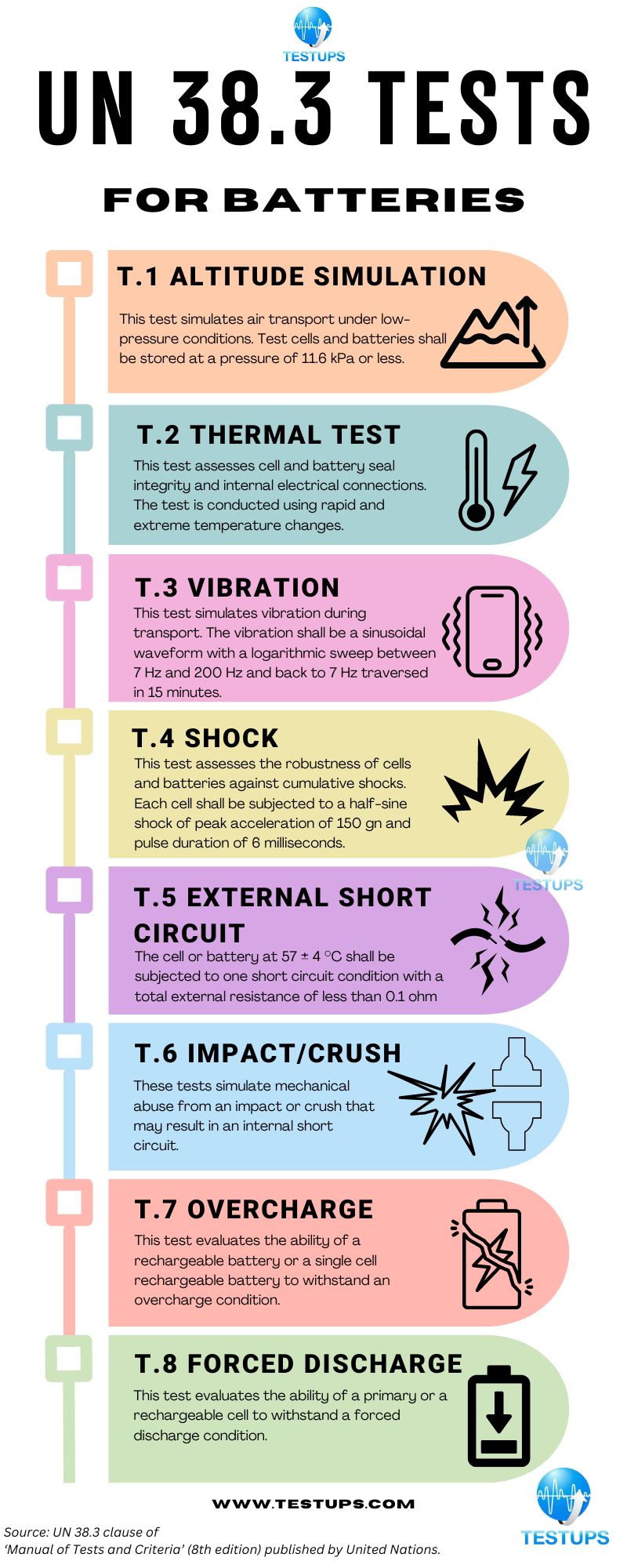

UN 38.3 is an United Nations’ requirement and includes eight different tests.

Have accredited battery testing services and test reports.

Contact us, send your battery’s technical features and get your quote.

Why UN 38.3 Testing?

United Nations is regulating transportation of batteries via its published document. One of them is UN 38.3 and it is related to transportation of lithium-ion and sodium-ion batteries and cells. UN 38.3 lists a set of tests to be applied to the battery that will be transported or marketed. All of these tests simulate the extreme conditions that can happen during the transportation of the battery.

About UN 38.3

United Nations (UN) regulates the transportation of batteries via its regulations. UN has published the document titled ‘Manual of Tests and Criteria’. 8th edition of this document is public and anyone can download it on UN’s official website. Here is the download link:

https://unece.org/transport/standards/transport/dangerous-goods/un-manual-tests-and-criteria-rev8-2023

The Manual of Tests and Criteria contains criteria, test methods and procedures to be used for the classification of dangerous goods according to the provisions of the United Nations Recommendations on the Transport of Dangerous Goods, Model Regulations, as well as of chemicals presenting physical hazards according to the Globally Harmonized System of Classification and Labelling of Chemicals (GHS). It therefore also supplements national or international regulations which are derived from the Model Regulations or the GHS.

38.3 article of this manual is titled Lithium metal, lithium ion and sodium ion batteries.

It shows the procedures to be followed for the classification of lithium metal, lithium ion and sodium ion cells and batteries.

UN 38.3 requires listed tests:

Test Number |

Test Name |

Purpose and Test Procedure |

T.1 |

Altitude simulation |

This test simulates air transport under low-pressure conditions. Test cells and batteries shall be stored at a pressure of 11.6 kPa or less for at least six hours at ambient temperature (20 ± 5 °C). |

T.2 |

Thermal test |

This test assesses cell and battery seal integrity and internal electrical connections. The test is conducted using rapid and extreme temperature changes.Test cells and batteries are to be stored for at least six hours at a test temperature equal to 72 ± 2 °C, followed by storage for at least six hours at a test temperature equal to – 40 ± 2 °C. The maximum time interval between test temperature extremes is 30 minutes. This procedure is to be repeated until 10 total cycles are complete, after which all test cells and batteries are to be stored for 24 hours at ambient temperature (20 ± 5 °C). For large cells and batteries the duration of exposure to the test temperature extremes should be at least 12 hours. |

T.3 |

Vibration |

This test simulates vibration during transport.Cells and batteries are firmly secured to the platform of the vibration machine without distorting the cells in such a manner as to faithfully transmit the vibration. The vibration shall be a sinusoidal waveform with a logarithmic sweep between 7 Hz and 200 Hz and back to 7 Hz traversed in 15 minutes. This cycle shall be repeated 12 times for a total of 3 hours for each of three mutually perpendicular mounting positions of the cell. One of the directions of vibration must be perpendicular to the terminal face. |

T.4 |

Shock |

This test assesses the robustness of cells and batteries against cumulative shocks.Test cells and batteries shall be secured to the testing machine by means of a rigid mount which will support all mounting surfaces of each test battery.Each cell shall be subjected to a half-sine shock of peak acceleration of 150 gn and pulse duration of 6 milliseconds. Alternatively, large cells may be subjected to a half-sine shock of peak acceleration of 50 gn and pulse duration of 11 milliseconds. |

T.5 |

External short circuit |

This test simulates an external short circuit.The cell or battery to be tested shall be heated for a period of time necessary to reach a homogeneous stabilized temperature of 57 ± 4 °C, measured on the external case. This period of time depends on the size and design of the cell or battery and should be assessed and documented. If this assessment is not feasible, the exposure time shall be at least 6 hours for small cells and small batteries, and 12 hours for large cells and large batteries. Then the cell or battery at 57 ± 4 °C shall be subjected to one short circuit condition with a total external resistance of less than 0.1 ohm. |

T.6 |

Impact/Crush |

These tests simulate mechanical abuse from an impact or crush that may result in an internal short circuit.Impact: The test sample cell or component cell is to be placed on a flat smooth surface. A 15.8 mm ± 0.1 mm diameter, at least 6 cm long, or the longest dimension of the cell, whichever is greater, Type 316 stainless steel bar is to be placed across the centre of the sample. A 9.1 kg ± 0.1kg mass is to be dropped from a height of 61 ± 2.5 cm at the intersection of the bar and sample in a controlled manner using a near frictionless, vertical sliding track or channel with minimal drag on the falling mass. The vertical track or channel used to guide the falling mass shall be oriented 90 degrees from the horizontal supporting surface.Crush: A cell or component cell is to be crushed between two flat surfaces. The crushing is to be gradual with a speed of approximately 1.5 cm/s at the first point of contact. The crushing is to be continued until the first of the three options below is reached. |

T.7 |

Overcharge |

This test evaluates the ability of a rechargeable battery or a single cell rechargeable battery to withstand an overcharge condition.The charge current shall be twice the manufacturer’s recommended maximum continuous charge current. The minimum voltage of the test shall be as follows:(a) when the manufacturer’s recommended charge voltage is not more than 18 V, the minimum voltage of the test shall be the lesser of two times the maximum charge voltage of the battery or 22 V.(b) when the manufacturer’s recommended charge voltage is more than 18 V, the minimum voltage of the test shall be 1.2 times the maximum charge voltage.Tests are to be conducted at ambient temperature. The duration of the test shall be 24 hours. |

T.8 |

Forced discharge |

This test evaluates the ability of a primary or a rechargeable cell to withstand a forced discharge condition.Each cell shall be forced discharged at ambient temperature by connecting it in series with a 12V D.C. power supply at an initial current equal to the maximum discharge current specified by the manufacturer.The specified discharge current is to be obtained by connecting a resistive load of the appropriate size and rating in series with the test cell. Each cell shall be forced discharged for a time interval (in hours) equal to its rated capacity divided by the initial test current (in ampere). |

How to choose tests for a specific battery type?

We derived below table from the Scope of UN 38.3:

Battery/Cell Category |

Tests that shall be applied |

All lithium cell types |

T.1, T.2, T.3, T.4, T.5, T.6, and T.8 |

All non-rechargeable lithium battery types, including those composed of previously tested cells |

T.1, T.2, T.3, T.4, and T.5 |

All rechargeable lithium battery types, including those composed of previously tested cells |

T.1, T.2, T.3, T.4, T.5, and T.7 |

Rechargeable single cell lithium batteries with overcharge protection |

T.7 |

A component lithium cell that is not transported separately from the battery it is part of needs only |

T.6 and T.8 |

A component lithium cell that is transported separately from the battery |

T.1, T.2, T.3, T.4, T.5, T.6, and T.8 |

All sodium ion cell types shall be subjected to tests T.1 to T.6. |

T.1, T.2, T.3, T.4, T.5, and T.6 |

All rechargeable sodium ion battery types, including those composed of previously tested cells |

T.1, T.2, T.3, T.4, T.5, and T.7 |

Rechargeable single cell sodium ion batteries with overcharge protection |

T.7 |

A component sodium ion cell that is not transported separately from the battery it is part of needs only |

T.6 |

A component sodium ion cell that is transported separately from the battery |

T.1, T.2, T.3, T.4, T.5, and T.6 |

A lithium cell, sodium ion cell or battery that is an integral part of the equipment it is intended to power that is transported only when installed in the equipment, may be tested in accordance with the applicable tests when installed in the equipment.

Are you looking for UN 38.3 Testing/Certification, Test System Supply, Laboratory Installation and Training Services?

Get Quote / Contact Us

info@testups.com