Anechoic chamber offers isolated environment for performing some tests and measurements. On this post, you will find every aspect of anechoic chambers. If you want to contribute to this post, add your comment by using Submit Comment button at the end of this page.

What is anechoic chamber?

Let us start checking the definitions of these two words from Cambridge Dictionary:

anechoic: not able to send back an echo (= a sound that reflects off a surface)

chamber: a room used for a special or official purpose, or a group of people who form (part of) a parliament

According to dictionary, we can define anechoic chamber as a room which is not able to send back an echo and used for a special purpose.

More technically, an anechoic chamber is a room designed to completely absorb reflections of either sound or electromagnetic waves. Anechoic chambers are mostly isolated from waves entering from their surroundings.

What are the functions of an anechoic chamber?

Anechoic chamber has two functions:

* To form a no reflection place

* To form isolated place

An anechoic chamber is used for either acoustic measurements or electromagnatic/RF measurements. Acoustic anechoic chambers do not allow reflection of sound waves inside the chamber and do not allow sound waves coming from outside. Electromagnetic/RF anechoic chambers do not allow reflection of electromagnetic waves inside the chamber and do not allow electromagnetic waves coming from outside.

Why anechoic chamber is used?

Main purpose is to create an reflection-free and noise-free test and measurement environment. Performing tests inside an anechoic chamber gives you much more reliable and accurate results when compared to testing outside.

Acoustic and electromagnetic measurements are the measurements of the strengths of frequencies. But, when performing these measurements, how will you avoid reflections from other objects, interfering signals or noise? You have to use special materials that absorbs unwanted signals and shielding that prevents interfering signals or noise.

Most of the acoustic, EMC, RF and antenna measurement standards require anechoic chamber to get accurate test results. Anechoic chambers are mostly used for product compliance tests and measurements. The product can be an audio device/component, electronic device/component/system, antenna or any product emits sound or electromagnetic wave.

Which standards are used for anechoic chambers?

Some of the anechoic chamber related standards are listed below.

| Purpose of Anechoic Chamber | Standard |

| Acoustics |

ISO 3745 |

| Acoustics |

ISO 3741 |

| Acoustics |

ISO 3744 |

| EMC |

CISPR 16-1-4 (chamber requirements) |

| EMC | CISPR 11 / EN 55011 (Industrial, Medical, Scientific) |

| EMC | CISPR 12 (automotive) |

| EMC | CISPR 14-1 / EN 55014-1 |

| EMC | CISPR 14-2 / EN 55014-2 |

| EMC | CISPR 24 (will be replaced by CISPR 35) |

| EMC | CISPR 25 (automotive) |

| EMC | CISPR 32 / EN 55032 (multimedia and IT equipments) |

| EMC | CISPR 35 / EN 55035 (multimedia and IT equipments) |

| EMC | CISPR 36 (new standard for automotive) |

| EMC | IEC 60601-1-2 / EN 60601-1-2 (medical) |

| EMC | ETSI EN 301 489-1 (radio devices and systems) |

| EMC | UNECE R10 (Regulation 10) (automotive) |

| EMC | RTCA DO-160 (avionics) |

| RF/Radio | ETSI EN 300 328 (radio devices and systems) |

The list includes both validation standards for compliance of anechoic chamber and test standards that anechoic chambers are referred.

Which measurements are performed in anechoic chambers?

Anechoic chambers are used for these tests and measurements:

Acoustics, ElectroMagnetic Compatibility (EMC), Radio Frequency (RF), Antenna, Microwave.

Measurement distances in anechoic chambers

Most of the test standards specify the measurement distance between the tested product (EUT/DUT/AUT) and the antenna. The measurement distances are mostly 1 meter, 3 meter and 10 meter. Different test limits are applied for each measurement distances.

Types of Anechoic Chambers

Depending on the application and measurement type, different types of anechoic chambers are used. Chamber types can be categorized into two:

1. Semi Anechoic Chamber (in which ground floor is reflective, thus it is called ‘semi anechoic’)

2. Fully Anechoic Chamber (all inner surfaces of the chamber are anechoic, thus it is called ‘fully anechoic’)

Product standards require anechoic chamber also defines the technical features of the anechoic chamber. For electronic products used in avionics, RTCA DO-160 standard defines the anechoic chamber parameters. For automotive, CISPR 12, CISPR 25 and CISPR 36 standards define the anechoic chamber parameters. For IT equipments, CISPR 32 refers to CISPR 16 compliany anechoic chambers. Same is for medical devices; IEC 60601-1-2 standard refers to CISPR 16 compliant anechoic chambers. If you are looking for anechoic chamber requirement of a specific product, firstly, you have to specify its applicable test or measurement standards.

EMC Anechoic Chambers

Let us look closer at anechoic chambers used for electromagnetic compatibility (EMC) tests. The purpose of EMC tests is either pre-compliance testing during product development or full-compliance testing during certification. The purpose defines the requirements of anechoic chamber that will be used. For full-compliance EMC testing, of course, you should follow the standard requirements and the anechoic chamber shall comply with what standard requires. Dimensions, validation measurements are essential for full-compliance EMC anechoic chambers. However, if you are interested in pre-compliance EMC testing, deviations from the standard is allowed since the chamber will not be used for full-compliance tests. You can perform pre-compliance EMC tests in an anechoic chamber which does not comply with the standard. The advantage of doing this is being flexible about the anechoic chamber dimensions and validation measurements.

| Comparison of pre-compliance & full-compliance EMC anechoic chambers | Product/EUT Stage | Benefits | Disadvantages |

| Pre-compliance EMC Anechoic Chamber | Development or R&D |

Budget friendly Smaller sizes |

Non-compliant with EMC standards (or partly compliant) Cannot be accredited due to deviations from the standard |

| Full-compliance EMC Anechoic Chamber | Certification or Ready to launch |

Compliant with EMC standards Can be accredited since it is fully compliant |

Costly Larger sizes |

Pre-compliance EMC Anechoic Chamber: This type of EMC anechoic chambers are mostly preferred by product designers, small and medium sized manufacturers, researchers, universities. If %100 compliance of anechoic chamber is not essential, this type chambers are beneficial due to they require smaller spaces and fulfil limited budgets.

Full-compliance EMC Anechoic Chamber: This type of EMC anechoic chambers are mostly preferred by test laboratories, large sized manufacturers, third party service providers. When %100 compliance of anechoic chamber is essential, this type of anechoic chambers are beneficial due to they are fully compliant with EMC standards and can be used as an accredited testing facility.

Which EMC tests require anechoic chamber?

Radiated Emissions and Radiated Immunity tests mostly require anechoic chamber by the reference EMC standards. Depending on the EMC test standard, the parameters (frequency range, measurement distance, dimensions of the site, site validations) are defined. If the radiated emissions test standard require antenna scanning, the height of anechoic chamber shall be heigh enough. For instance, CISPR 32 requires 1 to 4 meter antenna scanning during radiated emissions tests and antenna mast holding the antenna shall be placed inside the chamber. Radiated immunity tests require much more anechoic chamber validation measurements like Field Uniformity (FU).

Frequency ranges of EMC anechoic chambers

Lower frequency of an EMC anechoic chamber can go down to 10 Hz. Upper frequency of an EMC anechoic chamber mostly goes up to 40GHz. With special type of RF absorbing materials upper frequency can be up to 110 GHz.

Components of EMC anechoic chambers

EMC Anechoic Chambers are composed of some items. These components are listed below:

1. Galvanized Steel Plates (these plates are used for RF shielding)

2. Honeycomb Waveguide Airvents (these airvents are used for air ventilation to allow air fresh come inside)

3. EMI Filters (for power lines and cables) (these filters are filtering incoming power lines and other signal lines, ensuring no RF disturbance is coming from outside the chamber)

4. RF Absorbing Materials (Ferrite Tiles / Absorber Foam) (these materials are absorbing the RF signals coming on them, making the chamber ‘anechoic’)

5. RF Shielded Door (the entrance door of the anechoic chamber. metallic, flexible, conductive gaskets allow the door RF shielding the chamber when it is closed)

Validation Measurements of Anechoic Chambers

After installation of the anechoic chamber is completed, validation measurements can be either done by installation team or a third party external team. Third party measurements ensures compliance of the chamber installed. Third party validation measurements are optional services which have to be ordered during the quoatation of an anechoic chamber. Some service providers offer validation services without any accrediation even they are offering independent measurement results. Some other ones are offers these service under an ISO accredation scope.

6. Ground Floor / Plane (reflecting metallic ground)

7. Access Panels (I/O ports panels) (power line, I/O port sockets are placed on a panel, making easy to send/receive any signal from/to the chamber)

8. Waveguide Pipe (allows cables to placed between inside and outside the chamber, no connector or filter used, waveguide shape prevents RF leakage)

9. RFI Trap (a bundle of conductive smaller copper particles creating a ground and allows large sized cables to enter the chamber)

10. Anetenna Mast (placed inside the chamber to scan the antenna, if antenna scannnig is required)

11. Turntable (placed inside the chamber to turn the tested EUT 0-360 degree, if EUT turning is required)

12. Lighting System (EMI shielded lights are placed on the ceiling)

13. Monitoring / Camera System (EMI shielded camera and monitoring system is placed inside the chamber, if required)

14. Audio System (EMI shielded audio monitoring system is placed inside the chamber, if required)

If you need any anechoic chamber contact us.

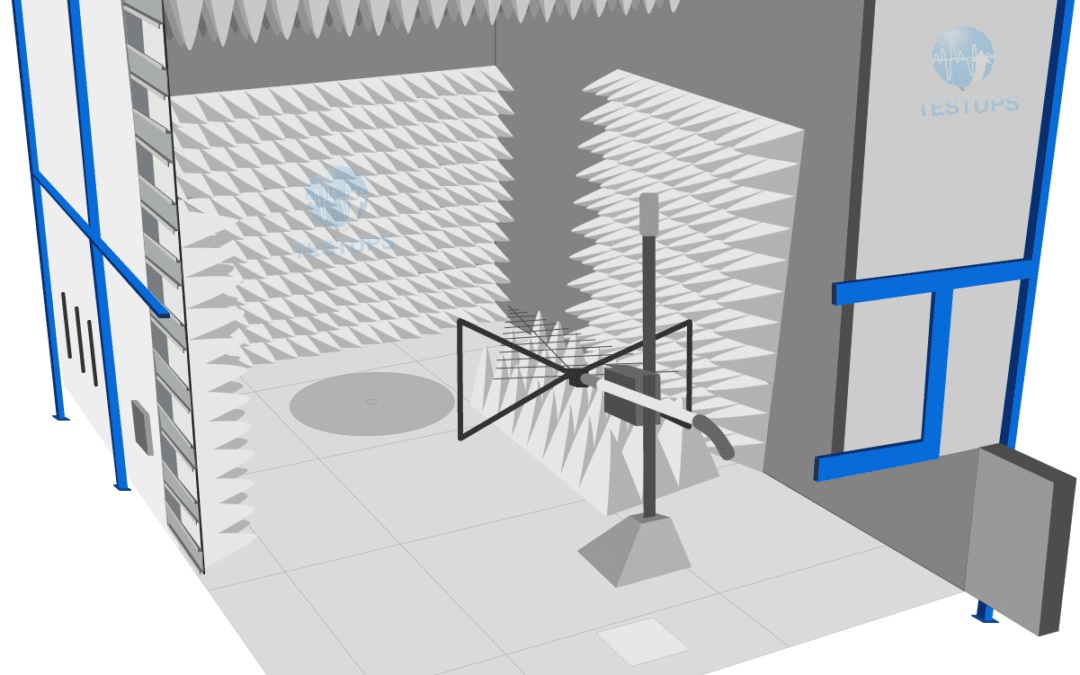

CISPR 25 EMC Anechoic Chamber

Below chamber is designed and manufactured for EMC tests of electronic components used in automotive. Reference standard is CISPR 25 and the chamber fulfils the requirement of this standard. RF shielding, RF absorbers and inner test setup requirements are taken into while desigining this chamber. It is designed and manufactured by our chamber manufacturer partner Diamond Microwave Chambers (DMC).

Recent Comments