Electromagnetic Compatibility (EMC) test labs have various needs.

Fundamental ones:

Service Scope Extension, Compliance to Standards, Calibration and Validation, Adapting to New/Updated Regulations and Standards, Maintenance and Repair, Keeping Key Staff and Knowledge

On this post we are analyzing the six common needs of EMC test laboratories.

1. Service Scope Extension

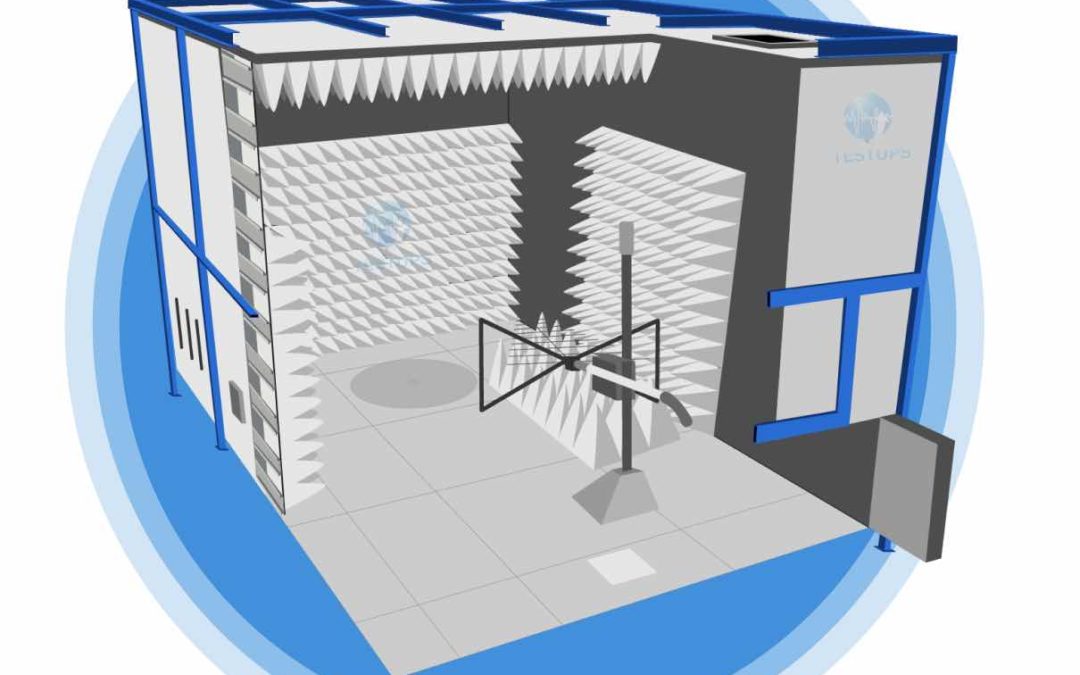

Every EMC test lab would like to extend its service scope by adding new capabilities, depending on the lab’s vision and field of area. An EMC lab which is able to perform only conducted and radiated emissions tests is probably to add new test setups like conducted immunity, radiated immunity, electrostatic discharge. Extension of scope is a force driven by the market. Existing and potential customers of the EMC lab would force them to extend the service scope. Growing EMC laboratories always extend their scopes for full coverage of the EMC standards. Adding new EMC test setups, instruments, chamber, test site, accessories, software, standards, test experts or any item to the laboratory is for extending the testing service scope. Service scope extensions are reflected to accreditation scope of EMC labs which are accredited and the lab can reach much more customers by this extension.

2. Compliance to Standards

Third-party and independent EMC test labs are forced to comply with EMC standards by using fully-compliant test systems, equipments and sites. The facility shall be compliant with the requirements of applied EMC standards. This need requires to perform EMC tests according to the relevant standard, without any deviation. Since deviation from the standard might mean non-compliance, this kind of EMC labs need fully compliant test setups. For instance, if the standard mentions about CISPR 16-1-1 compliance of an instrument, that instrument shall fully compliant with the referred standard. Compliance of EMC test equipments, systems and sites are ensured by calibration reports or certificates.

Pre-compliance EMC test labs does not need to use %100 compliant test systems since they have some tolerance to deviate from the standard. However, this does not mean that the degree of deviation is not important. It is important that pre-compliance EMC test results will be used to review product’s EMC compliance prior to full-compliance or certification tests. Thus pre-compliance EMC test labs are trying to make some paramters of their test systems compliant with the standards they apply, as much as they can do. Because this will ensure their measurement accuracy when compared to full-compliance test labs.

3. Calibration and Validation Services

EMC test labs need regular calibration and validation services for their test systems. For test instruments, recommended calibration period is 1 year. This period can be shortened if the instrument is used every day and can be extended to 2 years if it is rarely used. For calibration services, the laboratory might either contract with an external calibration laboratory or do theirselves if they are capable of doing. Accredited EMC test labs are forced to use external calibration service providers to ensure independency and being third-party. ISO/IEC/EN 17025 accredited calibration labs are issuing calibration reports and certificates to be kept by the EMC laboratory. Some pre-test checks and validations are done by the test staff of the EMC lab since the standard requires or allows.

4. Adapting to New and/or Updated Standards and Regulations

Technology is changing every day and product regulation and test standard committees are always following these changes. Regulations are standards are updated regularly and this affects the EMC test laborotories. They need to adapt to new and/or updated standards by applying the new or updated requirements. This might mean buying an extra test system, instrument, apparatus, software or building a new room, chamber or facility. Frequency extensions, test level updates and new test setups are the three main reasons for adapting new EMC standards or regulations. Professional and international EMC test labs are following draft standards and sending one of their staff to join standard committees. Joining standard committees brings benefits to that laboratory since they would be aware of the upcoming changes and adapt early. To join standard committees, you do not need to be a staff of an EMC laboratory, your interest and profeciency is much more important.

5. Maintenance and Repair Services

EMC test labs are performing tests by using test devices and facilities which might need periodic maintenance. Calibration focuses on the performance of the device or test site. Maintenance focuses on the details or parts of device or test site. For maintenance services, EMC test labs are engaging with device or test site manufacturers. If the test device is broken it needs to be repaired by its manufacturer or EMC expert repairer. Some device manufacturers does not prefer repairing and they may force the laboratory to replace the broken one with a new model. If this suggestion fits for both sides (the lab and device manufacturer) it might be useful even it is costly. Repair services are generally much more economic if the device is not totally broken.

6. Keeping Key Staff and Knowledge

This need is much more related to human resources policy of the laboratory. EMC labs which pay attention to keeping EMC knowledge and key laboratory staff in house, encourage their staff. How EMC labs keep their key staff? Paying high salaries, sending them to external EMC events, assigning additional responsibilities are a few ways to keep key staff in house. EMC knowledge of the laboratory needs to be documented, archieved and kept securely. The archieve related to EMC knowledge can be any document showing the experience of the laboratory, test procedures, event reports, test reports, presentations, internal or external trainings.

Recent Comments